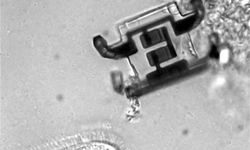

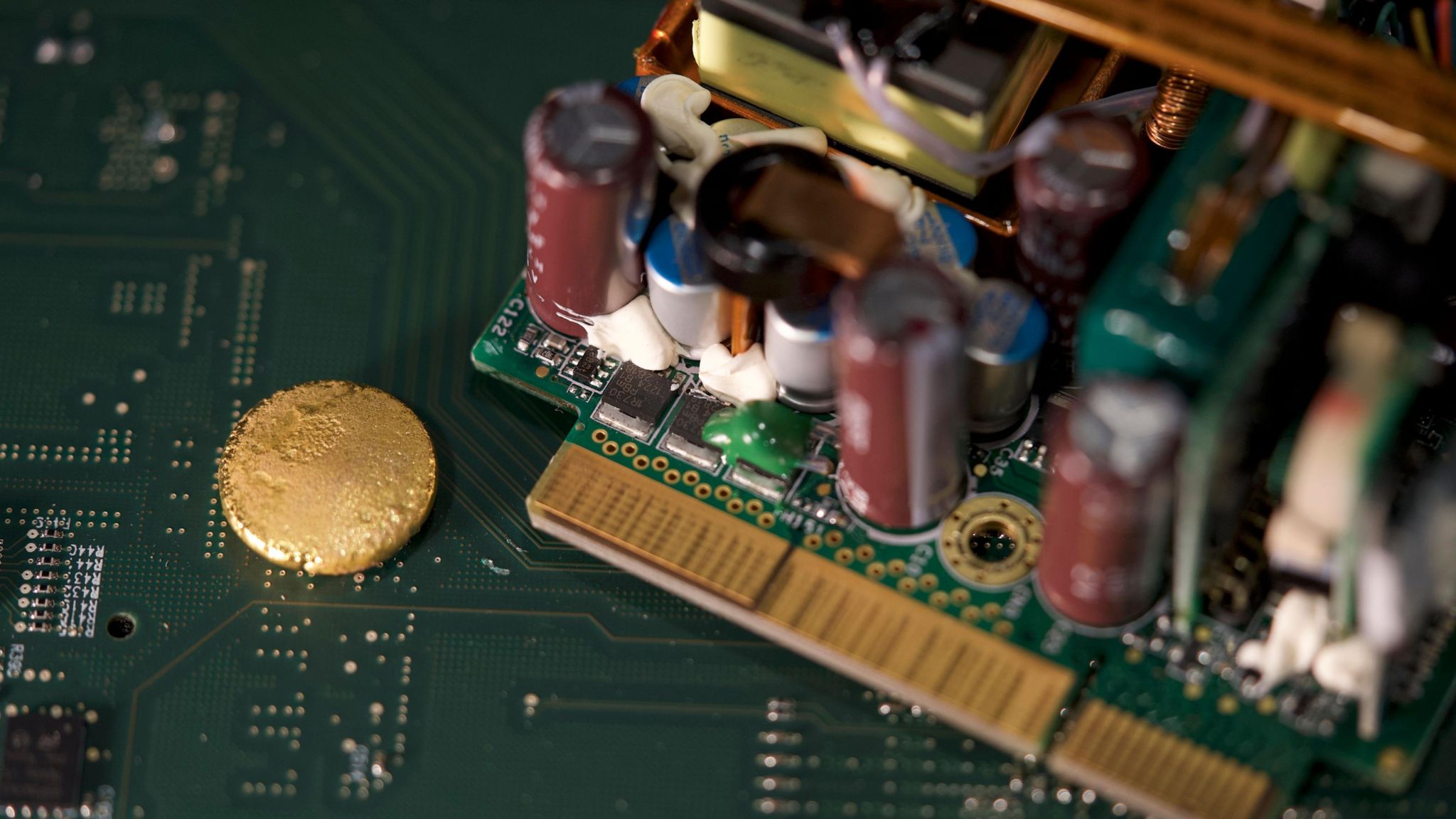

"The 3,700-square-meter facility at its South Wales site uses world-first patented chemistry from Canadian technology company Excir to extract gold in minutes from printed circuit boards (PCBs) found in everyday items such as televisions, laptops and cell phones. Excir's chemistry works at room temperature, creating a more energy efficient and cost-effective method of gold recovery.

The factory has taken innovative technology from laboratory to industrial level for the first time and has the capacity to process up to 4,000 tons of PCBs from e-waste each year. It provides the UK's oldest company with a new and more sustainable way to 'process' high-quality 999.9 purity gold.The recovered gold is already being used in the Royal Mint's luxury jewelry collection called 886.

According to the United Nations' Global E-waste Monitor, worldwide e-waste generation is increasing by 2.6 million tons every year. In 2022, a record 62 million tons of e-waste was generated, an 82 percent increase since 2010.The new factory offers a more sustainable solution to this growing environmental challenge. It is designed to ensure that valuable finite resources are recovered and other materials are properly processed for further processing."

According to the United Nations' Global E-waste Monitor, worldwide e-waste generation is increasing by 2.6 million tons every year. In 2022, a record 62 million tons of e-waste was generated, an 82 percent increase since 2010.The new factory offers a more sustainable solution to this growing environmental challenge. It is designed to ensure that valuable finite resources are recovered and other materials are properly processed for further processing."

Anne Jessopp, Chief Executive Officer of the Royal Mint, said: "The Royal Mint is transforming into the future and the opening of our Precious Metals Recovery factory is an important step in our journey. Not only are we preserving a finite number of precious metals for future generations, but we are also protecting the Royal Mint's renowned expert craftsmanship by creating new jobs and upskilling opportunities for our employees."